Exactly How an Optical Fibre Diameter Analyser Enhances Quality Control in Fibre Production

The assimilation of an Optical Fibre Diameter Analyser right into Fibre manufacturing processes stands for a considerable development in quality assurance methods. By providing real-time, specific measurements of Fibre diameters, this innovation attends to the vital need for uniformity in manufacturing requirements. With its ability to quickly identify variances and prompt restorative measures, the analyser not just boosts product integrity but likewise adds to general functional efficiency. As markets significantly prioritize top quality and compliance, comprehending the complete impact of such developments comes to be important. What effects could this have for the future of Fibre production?

Value of Fibre Diameter Measurement

Precise measurement of Fibre Diameter is essential in the field of optical Fibre technology, as it directly influences the performance and reliability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying ability, depletion, and total transmission performance. Accuracy in gauging Fibre Diameter makes sure that the optical properties are maintained within specified tolerances, which is important for ideal signal integrity.

Variations in Fibre Diameter can cause enhanced losses due to scattering and modal diffusion, influencing the top quality of information transmission. In high-speed communication systems, such discrepancies can cause substantial destruction of signal high quality, resulting in information mistakes and minimized performance. Consistent Fibre Diameter is essential for compatibility with connectors and splicing technologies, which are integral parts of Fibre optic networks.

Quality assurance processes in Fibre manufacturing heavily depend on exact Diameter dimensions to guarantee conformity with market criteria. By carrying out robust dimension techniques, makers can enhance item reliability, reduce waste, and boost overall system efficiency. Thus, the value of Fibre Diameter measurement can not be overemphasized, as it works as a keystone in the development of optical Fibre technology and its applications in contemporary communication networks.

How the Analyser Works

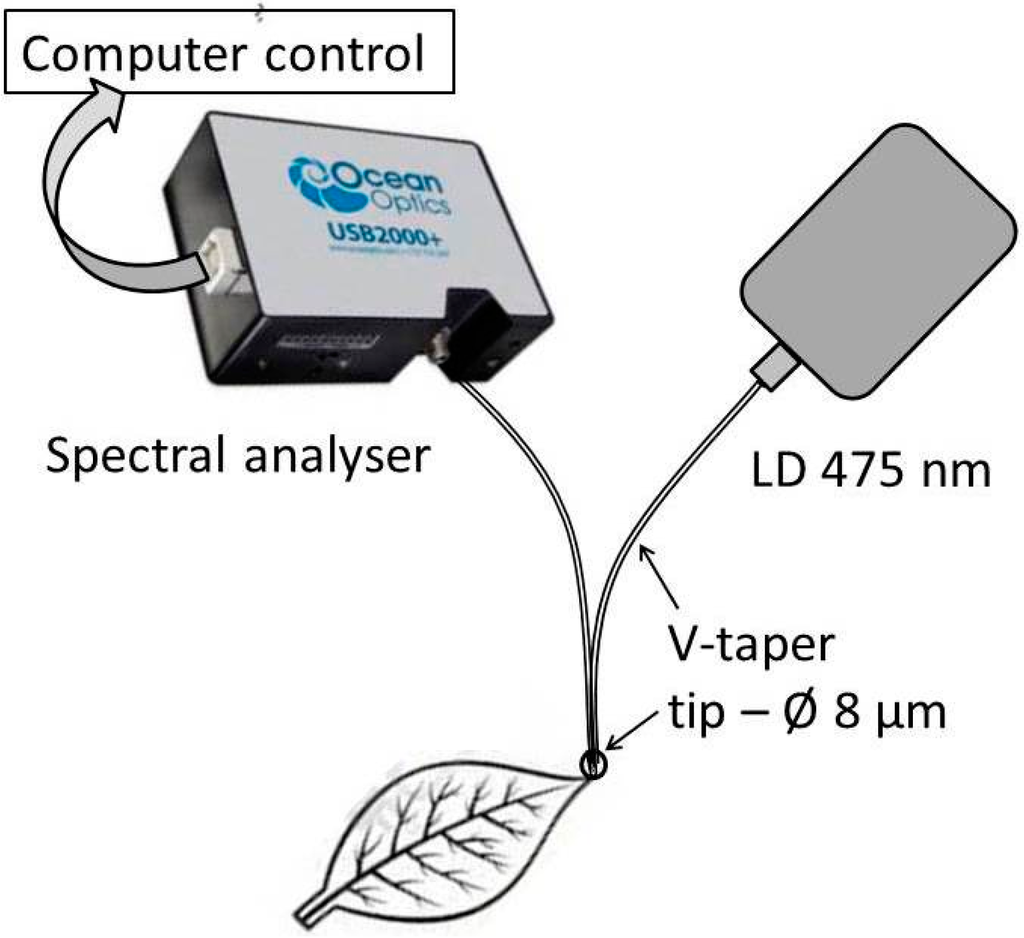

The reliable measurement of Fibre Diameter counts on advanced analytical strategies that ensure precision and integrity in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser technology and advanced picture handling formulas to accurately evaluate the Diameter of fibers as they are generated

Initially, a laser beam is guided at the relocating Fibre, developing a cross-sectional darkness. The analyser captures this shadow utilizing high-resolution cams placed strategically along the production line. The caught pictures are after that refined in real-time to figure out the Fibre's Diameter with remarkable accuracy.

The system uses advanced algorithms that represent different aspects, consisting of variants in light strength and ecological problems, to boost measurement reliability. It can spot minute modifications in Diameter, such as changes that may take place throughout the production procedure.

Additionally, the analyser is qualified of managing several fibers all at once, increasing throughput without endangering accuracy. By providing instant comments on the Diameter, the Optical Fibre Diameter Analyser plays a crucial role in preserving rigorous quality assurance requirements, making sure that the end product satisfies sector specifications and consumer demands.

Benefits of Real-Time Monitoring

While standard approaches of monitoring Fibre Diameter typically include time-consuming post-production checks, real-time monitoring significantly enhances the efficiency and top quality of optical Fibre manufacturing. optical fibre diameter analyser. This aggressive technique enables manufacturers to identify inconsistencies in Fibre Diameter as they happen, as opposed to waiting until manufacturing is total to evaluate quality

By continually gauging the Diameter throughout production, producers can make sure that the fibres fulfill rigid requirements, causing reduced irregularity and enhanced consistency. Real-time surveillance also makes it possible for prompt rehabilitative actions to be taken, decreasing waste and avoiding malfunctioning fibres from going into the supply chain.

In addition, this technology assists in boosted data collection and analysis, supplying understandings into manufacturing fads and potential areas for enhancement. Such data-driven decision-making encourages manufacturers to optimize processes and preserve high requirements of quality assurance.

On top of that, real-time monitoring fosters a culture of constant enhancement within the manufacturing setting. Staff members are a Visit Your URL lot more involved when they can see the influence of their operate in real-time, leading to heightened accountability and a commitment to excellence. In general, the application of real-time tracking systems in optical Fibre manufacturing translates to exceptional product quality and increased customer complete satisfaction.

Influence On Production Efficiency

Implementing optical Fibre Diameter analysers significantly enhances manufacturing performance by simplifying the production process. These devices facilitate continuous surveillance of Fibre Diameter, allowing suppliers to identify inconsistencies in real-time. By recognizing variances immediately, assembly line can be adjusted promptly, lessening downtime and visit minimizing the possibility of producing malfunctioning items.

Additionally, the integration of these analysers right into the manufacturing process enables far better resource allocation. With exact Diameter measurements, drivers can enhance material use, making sure that resources are not thrown away on problematic fibres. This accuracy also adds to less scrap and revamp, inevitably decreasing manufacturing costs.

The automation given by optical Fibre Diameter analysers decreases dependence on manual examinations, which are prone and commonly time-consuming to human error. Because of this, workers can concentrate on more critical tasks, improving total efficiency.

In addition, the data produced from these analysers can educate process enhancements and promote better decision-making. By examining fads in Fibre Diameter variations, suppliers can implement positive actions to enhance production methods and keep regular quality. In summary, optical Fibre Diameter analysers play a crucial function in improving manufacturing efficiency, resulting in higher high quality result and enhanced productivity.

Case Studies and Success Stories

Across different markets, instance researches highlight the transformative influence of optical Fibre Diameter analysers on manufacturing procedures. One prominent example is a leading telecommunications company that encountered difficulties with irregular Fibre diameters, causing boosted denial prices. By incorporating an optical Fibre Diameter analyser, the business accomplished real-time tracking of Fibre dimensions, resulting in a 30% reduction in problems and significant cost savings.

Furthermore, a study institution concentrating on advanced products utilized optical Fibre Diameter analysers to fine-tune their speculative processes. The analyser's capability to supply comprehensive understandings into Fibre uniformity allowed the growth of ingenious products with enhanced efficiency qualities.

These success tales emphasize the vital duty of optical Fibre Diameter analysers in enhancing quality control, boosting production performance, and driving development throughout diverse industries.

Verdict

In conclusion, the Optical Fibre Diameter Analyser plays a crucial duty in boosting top quality control within Fibre production. As demonstrated through various case researches, the analyser confirms crucial for attaining premium item high quality in Fibre manufacturing.

The application of optical Fibre Diameter analysers permitted for strict top quality control, guaranteeing that the generated fibres fulfilled exacting industry criteria.In conclusion, the Optical Fibre Diameter Analyser plays an essential role in improving top quality control within Fibre manufacturing.

Comments on “Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications”